What is Thin Porcelain Tile

Why Choose Thin Porcelain Tiles?

Tiling with Thin Tiles

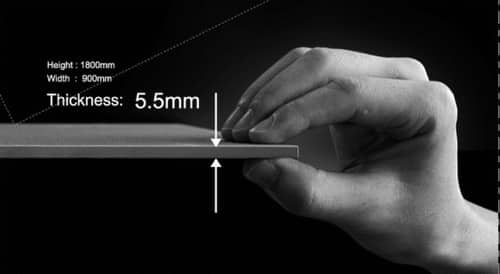

(3 to 6mm thickness)

A few years ago, a new trend appeared in the tiles showrooms: the thin tiles. They are made in ceramic, and their weight is two times lighter than a standard tile.

To obtain a professional and clean result, special care should be taken when handling and fixing these tiles.

Until recently, floor tiles have been 8 to 12mm thick and tiles less than 7.5mm were not intended for floors. However, tiles engineered to be thinner have now entered the marketplace. Made of porcelain, they are being marketed as “thin tiles.” Are they the same as their thicker brethren, except thinner? Being thinner they take fewer resources to manufacture and ship, but where and when can they be used?

What are Thin Tiles?

There are three categories of products being promoted as thin tiles. All three are 6mm or less, but there are important differences between them.

In the first category, tiles are formed using the traditional dust pressing methodology. Such products are similar to traditional pressed porcelain tiles, except they are only 5 to 6mm thick and have a lower breaking strength.

In the second category, tiles are formed using a lamina process. Lamina tile products are produced in large, thin ceramic sheets, from which individual tiles can be cut. They are 3 to 4mm thick, are much lower in strength, and bend sufficiently to be installed on curved surfaces.

In the third category of thin tiles, lamina products are reinforced with backing materials. These backing materials are fiberglass or polymeric materials woven into a reinforcing mesh. Fused directly to the back of the lamina products with epoxy or other resin adhesives, the reinforced lamina tiles can be bent further and better resist breakage.

Strength Concerns

All thin tiles, regardless of category, have a much lower breaking strength (less able to resist breakage when unsupported) than regular ceramic tiles.

The ANSI A137.1 breaking strength requirement for floor tiles is 250-lbs. To date, no thin tile has met this requirement. Compared to regular tiles, thin tiles also behave differently when subjected to impact. Because they are thinner, they are less able to resist impact loading when unsupported.

Even thin tiles with reinforced fiberglass backings have low impact resistance when unsupported, although sometimes the tiles puncture before they break.

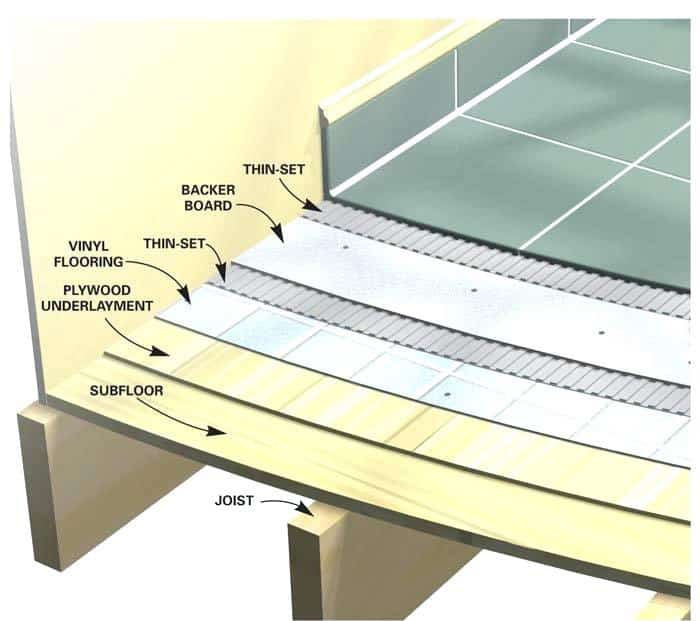

In summary, thin tiles must be fully supported (i.e. installed with 100% coverage) to prevent damage from loading or impact.

Technical Constraints

• Thin tiles are available in various sizes: from 30 x 30 cm to 100 x 300 cm. The solutions given in this case apply for tiles sizes up to 60 x 60 cm (maximum size of tile included in standards for tile adhesives).

For tiles sizes above that, please consult technical department.

• Thin tiles generally have a thickness between 3 and 5 mm, and a low porosity.

• If the thin tile is supplied with a mesh on the back, the mesh and mesh adhesive should not cover more than 25% of the back of the tile, otherwise it could affect the final adhesion.

• Because of their low thickness, thin tiles are also more flexible than standard tiles.

A deformable or flexible tile adhesive should be used.

• Because of their large size and their high flexibility, it is highly recommended to use a fast-setting tile adhesive, to avoid bending/ warping issues that would let the edges of the tiles go up in arrow shape.

The use of a fast-setting tile adhesive will ensure that all the parts of the tile are well bonded with the substrate.

• These thin tiles cannot be applied in high-traffic areas.

Not all the thin tiles have the same shock resistance.

Therefore, some of them cannot be applied on floors or over a heated floor.

It is important to check the scope of use of the tiles given by the tile manufacturer before applying them.

• Thin tiles need a very smooth and flat substrate (old tiles for instance). Due to their low thickness, it is not possible to correct the flatness defaults of the substrate. As well, to avoid that the tile adhesive goes out from the joints during application, it is recommended to use a tile adhesive with a not too fluid consistency

Selecting Thin Porcelain Tile for your project instantly delivers all the advantages that come with ultra-thin lightweight porcelain tile technology. The uncompromising and stunning combination of weight, size, strength and style come together to make Thin Porcelain Tile the first choice for all interior and exterior projects.

12 reasons to choose Thin Porcelain Tiles

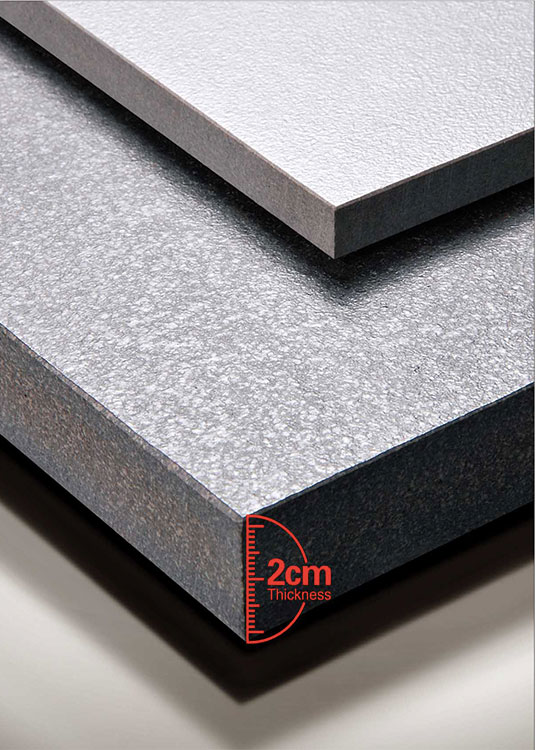

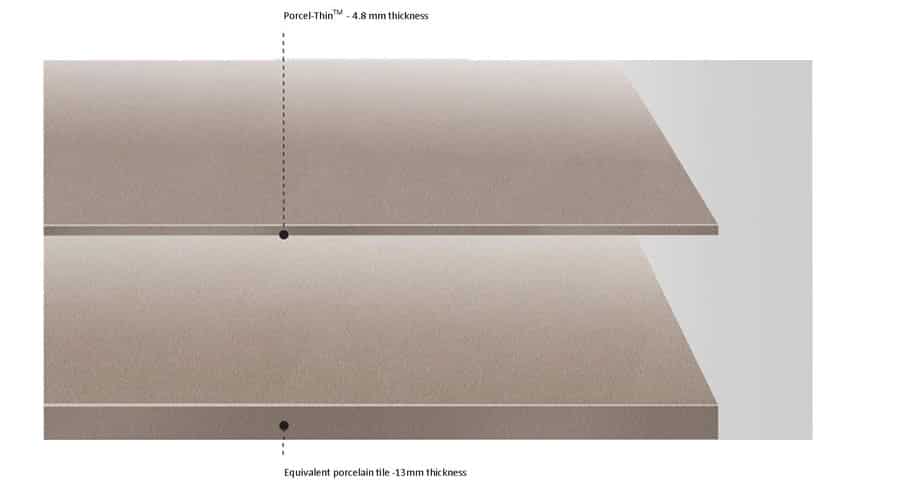

- At just 4.8mm, Thin Porcelain Tile is less than half the thickness of standard 13mm porcelain tiles.

- Ultra-thin means less material making Thin Porcelain Tile less than half the weight of conventional 13mm porcelain tiles.

- The reduced weight of Thin Porcelain Tile enables extra-large format 1200 x 600mm tiles that can be handled by one person.

- The Thin Porcelain Tile 1200 x 600mm standard format gives faster coverage and fewer grout lines saving in time and materials.

- Thin Porcelain Tile can be applied directly over existing tiles, reducing the time and costs of removal and making good.

- Thin Porcelain Tile comes in an unparalleled choice of colours, textures and finishes.

- Thin Porcelain Tile is easy to cut using conventional tiling tools.

- Ultra-low water absorption of below 0.5% is significantly better than the industry standard of 2-3%, which helps Thin Porcelain tile resist dirt and stay cleaner for longer.

- Independent tests confirm that Thin Porcelain Tile is nearly twice as strong as conventional, full thickness porcelain tiles and is resistant to water, frost, fire and heat.

- Ultra-thin Porcelain Tile will not deform, crack or fade and can be used on floors, walls and ceilings in both indoor and outdoor applications.

- Lightweight Thin Porcelain Tiles reduce the overall loading in building construction.

- The Porcelain Thin Tile manufacturing process has a significantly lower environmental impact than standard porcelain products.

Why Thin Porcelain Tiles So Strong?

- Independent tests prove that thin porcelain tiles are nearly twice as strong as thicker, conventional porcelain tiles. Highly resistant to water, frost, fire or heat, thin porcelain wall and floor tiles are also incredibly hardwearing, withstanding even outdoor usage without deforming, cracking or fading.

- Despite their inherent strength Thin Porcelain wall and floor tiles are still easy to cut and shape using only conventional tiling tools.

- Unlike inferior thin porcelain tiles Thin Porcelain products DO NOT contain or require any strengthening meshes or materials. This addition often causes lesser porcelain tile products to fail as the fibreglass mesh they must use to compete with inherently robust porcelain tiles expands and contracts at different rates – causing inferior porcelain tiles to break down.

- Measuring only 4.8 mm thick porcelain tiles are incredibly lightweight. This combination of reduced weight and incredible strength mean that even large format tiles of 1200 x 600 mm and 1800 x 900 mm can be easy handled by a single person.

- These extra-large tiles also give faster coverage with fewer grout lines to spoil the overall look. Needless to say, using fewer tiles also results in a saving for both time and materials.

- Porcelain Tiles, including large floor tiles, are manufactured with the environment in mind. Compared to standard ceramic tiles Thin Porcelain production process uses 60% less mineral resources, 40% less energy and produces 50% less carbon.

Comments (4)

Really informative and great content you have shared here regarding thin porcelain.

Ref: application of thin porcelain tiles. In which cases of options the thin porcelain tiles win over others and what market prospects exist in the Asian countries? A detailed answers would be appreciated.

I need thin (3.5mm – 5.5mm) slate looking tile to restore a slate patio table. I only need <20 sq. ftl

Hello There,

How are you?

Greeting from Silon Granito LL,

We are producing slim tiles in 600x1200mm size in 5mm thickness,

below my email if you have any questions please feel free to contact me.

kuldeep@silon.in

http://www.silon.in